Heat Pump Installer of the Year shares his expert heat-pump tips

We set out to discover what we could learn about choosing and using heat-pumps from one of the best installers in the UK. And he had some great advice to share

It’s becoming clear that the best way to ensure success with a new heat-pump system is to pick a great installer. Heat-pump technology has come on in leaps and bounds, and modern models can work in almost any home. What you do need, however, is the right engineer to design and install your system. To find out what’s involved, we talked to Stuart Sugden, recently crowned HPM Heat Pump and Hybrid Installer of the Year 2024, to find out what makes a great installer, how they get the best from renewables, and what you should look for when choosing someone to put in your new heating system.

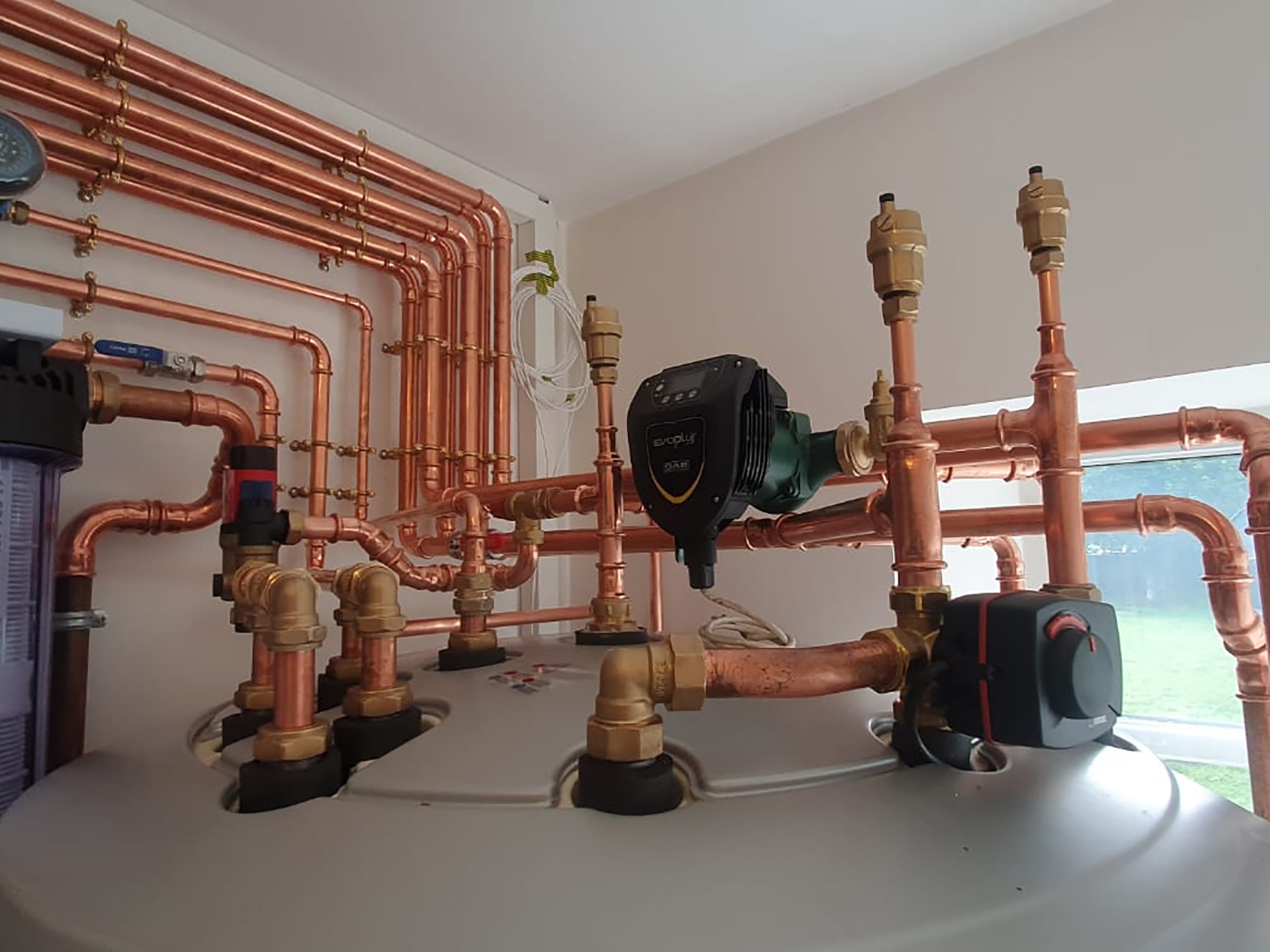

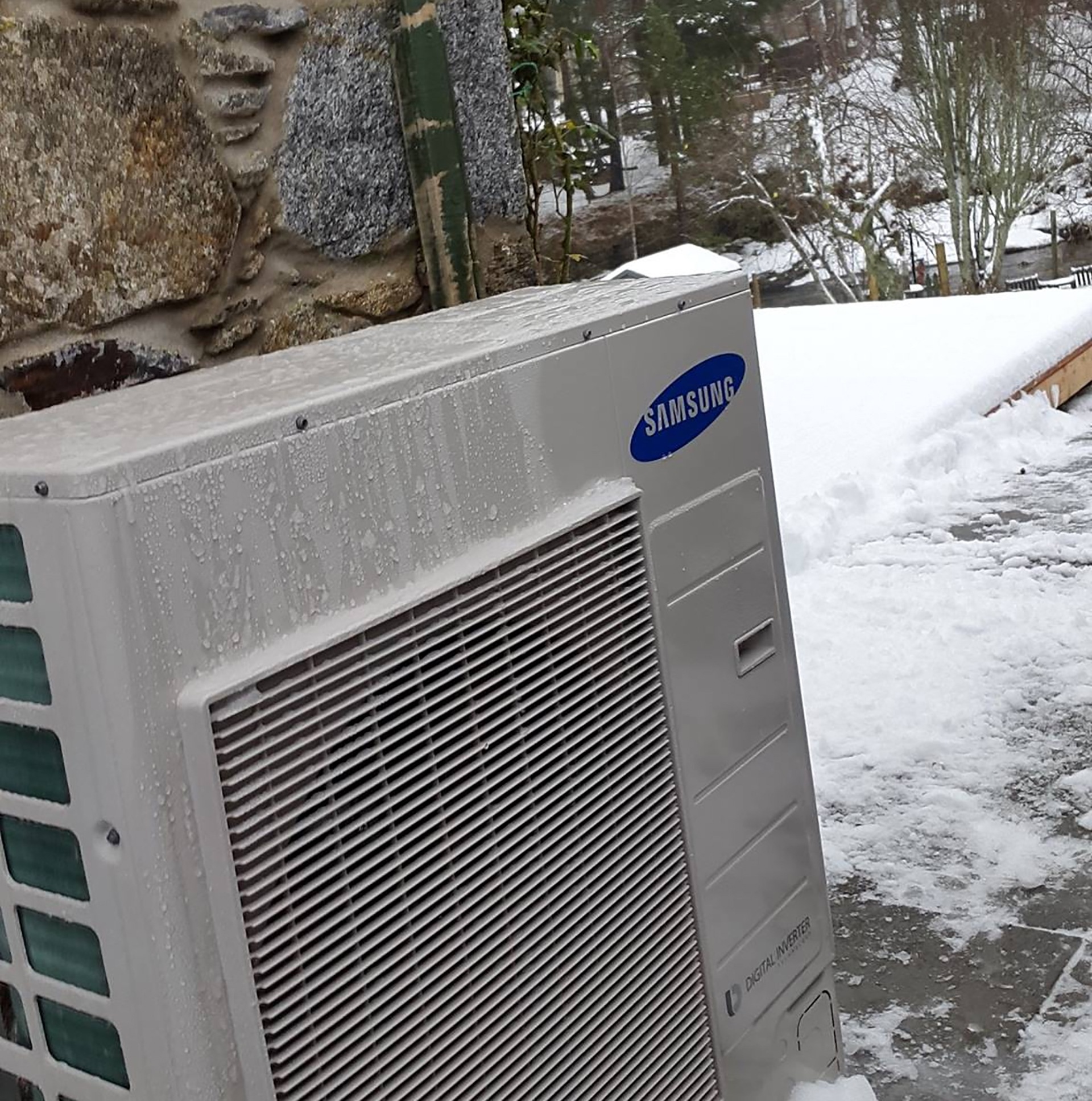

- Image credit: Sugplumb

Stuart Sugden runs his own company, Sugplumb, in Aboyne, Aberdeenshire, Scotland. His company installs air- and ground-source heat pumps as well as traditional heating systems, plus a whole range of renewables, including solar thermal, solar PV and pellet boilers, as well as MVHR ventilation systems.

- Image credit: Sugplumb

Stuart trained as a traditional heating engineer, but got interested in the potential of heat pumps early on. In 2010, he gained his MCS (Microgeneration Certification Scheme) certification to enable him to work with the new low-carbon systems. After more than a decade working with the new technology, Stuart is still a believer but feels that getting the system design and set-up right is the key to everything. He says, “Often we’ll get calls to the office saying, ‘Oh, I have a heat pump, it’s rubbish, it doesn’t work. Cost a fortune, you know. Can you help?’ And, every time, we say, ‘It won’t be the heat pump that’s the problem….’ And more than nine times out of ten – probably 99 out of 100 – it isn’t the heat pump that’s the problem, it’s the installation that’s been the problem.”

Installation importance

So how do you get it right? “Heat pumps rely on flow, so you do have to make sure that your pipe sizing is correct. They are a low-heat system, so, if you’ve got a house that is designed for an oil or gas boiler, for example, they’re designed to flow at 70°C, whereas the heat pump is ideally going to run around 40 or 45°C. So there’s a massive difference, which means the radiators in the system probably aren’t big enough. And, obviously, it’s our job to calculate that and work that out properly to ensure the system operates correctly at a lower temperature.”

Stuart is fully committed to the low-temp heating revolution. He says: “It doesn’t take a rocket scientist to work out that the more you heat something, the more it costs. So, even with oil or gas, we design everything to work at as low a temperature as possible now because, the more you heat it, the more energy it takes, and, therefore, the more money it costs.”

- Image credit: Sugplumb

Consistent low heat

Stuart is also keen to point out how important it is that users change their mindset to adapt to the way low-temp systems work. He explains, “The other thing about the heat pumps we use is that they are inverter driven. So, unlike with an oil boiler that’s either on – flat out – or it’s off, what an inverter-driven heat pump will do is come on and ramp itself up by increasing fan speed and compressor speed and using more energy. And then, once everything comes up to temperature, it sees that temperature rise and actually slows itself down and ramps itself down. Then it comes a point where it’s using a very small amount of energy and it’s just topping itself up. The idea is you run your heating for long periods and don’t have too big a temperature change for off periods. We just have what we call ‘setback temperatures’.

“Traditionally people would have the heating on in the morning for three or four hours to heat the property, go away to work, let the whole house cool down. Then, in the evening, it comes back on again to heat the house back up for people coming home. But those massive peaks and troughs in a graph are using lots and lots of energy, whereas if we can stabilize that and take that down and use the inverter-driven heat pump to just use a little energy over a longer period, it actually ends up using less. So your house is always comfortable. And it’s a better environment for everything.”

- Image credit: Sugplumb

Customer education

Stuart sees educating customers about their new systems as a crucial part of his job. People need to be taught a whole new way of thinking about how to use their heating. “Our handovers with the customer are really quite intensive because we have to educate them into how best to use their system. In people’s minds, if they leave it on it’s going to use lots and lots of energy, and that’s going to cost them a fortune. So you do have to educate them and you do have to discuss it with them and show them.

“Last year a customer phoned me and said, ‘Look, to be honest, the heat pump does seem to be using more energy than we had expected and we’re actually only using half the house.’ I said, to myself, ‘That seems strange.’ And I thought, ‘Well, what do we mean by only using half the house?’ I went out to have a look and they had just left the landing radiator on the first floor of the property, and turned off all the other radiators upstairs. So, it was trying to heat the whole of the upstairs of the house and it was never going to manage. That just meant the heat pump was running on and on and on and on and never making its target temp. They actually saved money by turning the other radiators back on to let them do what they needed to do. The homeowner thought they would turn things off to try and cut costs, but it doesn’t work like that.”

Radiators aren’t hot

Educating customers is crucial when it comes to another aspect of heat-pump operation: managing expectations about radiator temperature. Stuart says, “I say to customers, ‘If I come back to your house and touch your radiator and it’s only lukewarm but your house is comfortable: mission accomplished. What we don’t want is to come in and feel your radiators roasting hot. We want to have them so they only do enough.’ It’s about us as engineers calculating how much heat loss comes from that building and matching that to the output of the radiators, and of the system, while keeping that flow temperature as low as possible.”

Weather compensation

Stuart is also keen to point out the importance of what he regards as another vital component of a good system: weather compensation. This is a heating-system controller featuring an external temperature sensor. It maintains comfortable and consistent temperatures inside the house by varying the flow temperature from the heat pump according to the outside temperature: the warmer it is outside, the lower the flow temperature, and that of the radiators. Stuart says, “We weather compensate all our systems. So, on a colder day, the radiators run at a slightly hotter temperature, but on a warmer day, they don’t have to work so hard. It takes a little bit of time to do, but it makes a massive, massive difference.”

- Image credit: Sugplumb

One of the managers at Stuart’s company Sugplumb runs his own heat-pump system using weather compensation alone, with no time clocks, radiator thermostats or the like. The heat pump runs 24-7, and never needs adjusting, and the house remains at a constant 20°C.

Tailored installations

Part of what makes an engineer like Stuart good at what he does is his ability to recognise and take into account the different needs of each of his customers. He explains how he tailors installations: “You could have a street of houses that are all the same, but, if you put heat pumps in all of them, you might end up setting them all up differently. One customer might want it at 18°C all the time, and when they retire of an evening, they put on the fire in the lounge, which just lifts the temperature enough for them to be comfortable. We have several customers who do that. But then the next customer might want a constant 24°C because that’s what they like. And they want to be able to walk around the house in shorts and t-shirt and be roasting hot. You have to design it around the customer’s needs, set it up with them, and then actually show them how they can make adjustments as well.” He follows up with customers post-installation, too, to check their new system is meeting their needs.

Heat pumps work here

Stuart has no truck with the idea that British homes are just too old and draughty to be heated with heat pumps. “That’s nonsense,” he says, though he admits there are some properties he has visited that have been too large to be heated by a single large (16kW) heat pump. At that point, he will consider a cascaded system, and advise the homeowner to think about upgrading their insulation. He finds the thick, granite walls common to many homes in his patch of Royal Deeside retain heat very well.

- Image credit: Sugplumb

Home Energy Scotland

As he works in a rural area, he installs ground-source pumps as well as air-source ones. The cost of these can be double the cost of air-source pumps, however, and this puts many people off, as there is no higher government grant for more costly set-ups. The Home Energy Scotland grant available north of the border, is similar to England’s Boiler Upgrade Scheme. The standard grant is the same, at £7,500. However, an extra £1,500 ‘rural uplift’ payment is available too, and most of Stuart’s customers qualify for this. Plus interest-free loans are also available to cover the balance of the installation cost. Stuart explains, “The loan can be taken out over 10 years, and, nine times out of 10, the customer can save enough over the 10 years – versus what they would have paid with an oil-fired boiler – to pay the loan.”

So what lessons can we learn from the heat-pump installer of the year that could help inform the government’s national rollout of heat pumps, which has so far proved less than stellar? The two big takeaways are the vital importance of engineering excellence and customer education. The more generous grant regime in Scotland also helps Stuart’s customers, especially the access to government-backed interest-free loans.

Training more installers

Another key to securing low-carbon heating take-up will be ensuring there are enough trained heat-pump installers. In 2023, the Heating and Hot Water Industry Council suggested another 150,000 trained heat-pump engineers would be needed if the government’s target of 600,000 new installations a year is to be achieved (that’s three times the government’s estimate of the installers needed).

Although a fan of the training on offer in the official MCS scheme, Stuart is very aware of the barriers to take-up. He says, “It costs a lot of money. You need to be a company of a certain size in order to be able to facilitate that because you need to have someone in the office. Which puts a lot of guys off. There’s a lot of associated costs with it. It’s very intense. And that puts a lot of good people off.” Perhaps this helps explain why we are still so far from having the number of installers we need.

How to find a good installer

As for what people should look for when they are looking for an installer, Stuart advocates word-of-mouth recommendations and consulting online reviews. Recipients of Home Energy Scotland grants are obliged to leave a review of their installer as a condition of their grant. This means there is a lot of information available to help customers north of the border choose a supplier. Many of these reviews are on the Energy Saving Trust’s Renewable Installer Finder, which also contains some reviews of installers in the rest of the UK. The list of MCS certified renewables installers is here.

- Image credit: Sugplumb